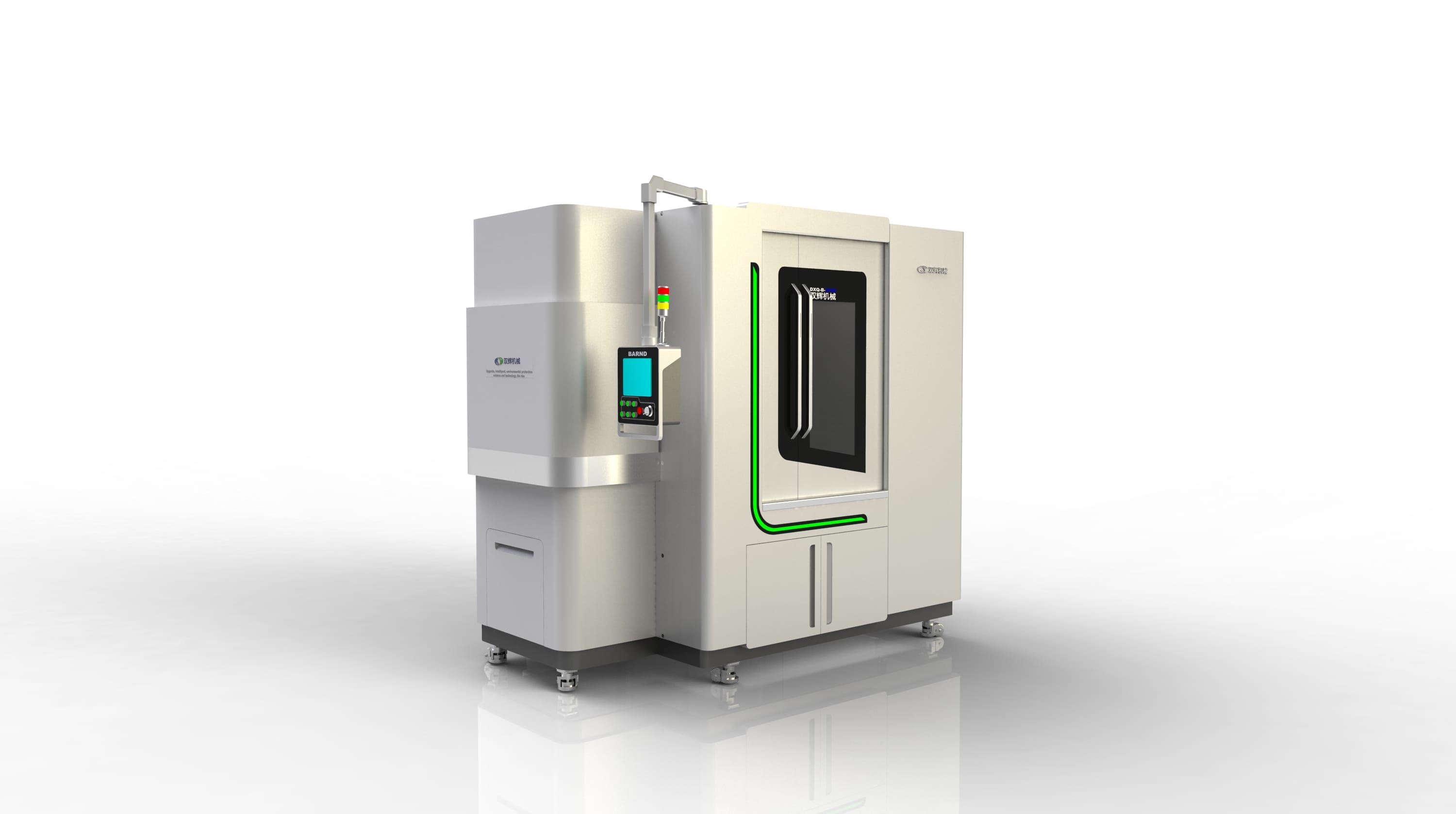

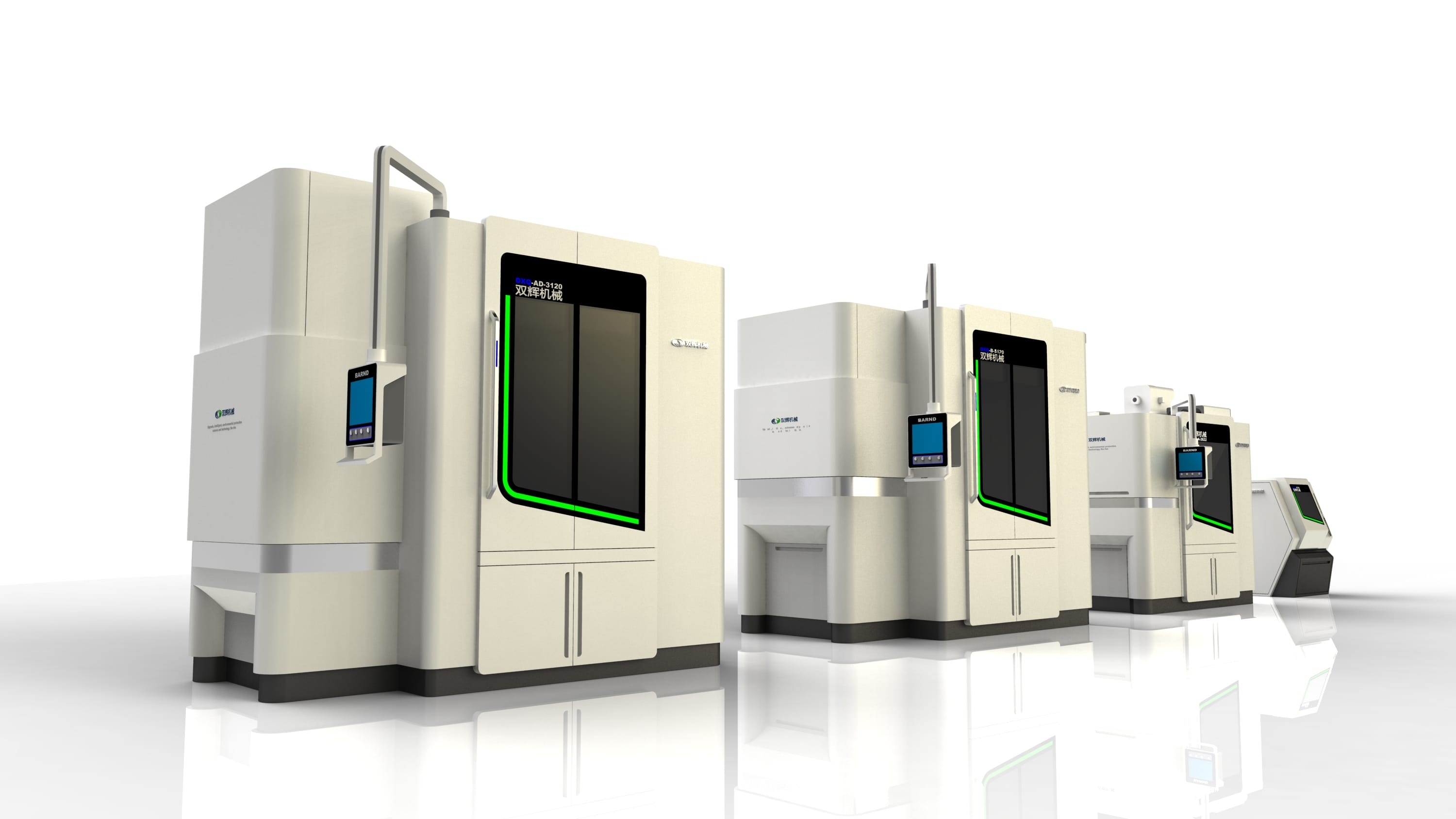

A Multi Wire Saw is a device used for silicon wafer cutting and processing. It uses the high-speed reciprocating motion of metal wires to bring abrasive into the semiconductor processing area for grinding, thereby cutting hard and brittle materials such as semiconductors into hundreds of thin sheets at once. This cutting method not only improves production efficiency and yield, but also has the characteristics of low loss, high precision, and high speed during the processing. The application of multi wire cutting machines in the field of silicon wafer processing is gradually increasing, especially in the field of large-diameter silicon wafer processing, and there is a trend of gradually replacing inner circle cutting machines. twelve

The technical characteristics of multi wire cutting machines include:

¡¤High efficiency: capable of cutting hundreds of thin sheets simultaneously, improving production efficiency.

¡¤Low loss: Compared with traditional cutting methods, multi wire cutting machines have a lower cutting loss rate and less inter piece cutting loss.

¡¤High precision: capable of achieving high-precision cutting of semiconductor materials and various hard and brittle materials.

¡¤High speed: Grinding metal wires through high-speed reciprocating motion improves cutting speed.

In addition, the multi wire cutting machine also has the following advantages:

¡¤Low Bending and Warp: The bending and Warp of the cut chip are small, ensuring the flatness of the chip.

¡¤Good parallelism and total thickness tolerance: Good parallelism (Tarp) and small total thickness tolerance (TTV) improve the quality of the chip.

¡¤Low roughness and high chip yield: The surface damage layer of the processed chip is shallow, the roughness is small, and the chip yield is high during slicing.

The multi wire cutting machine has integrated modern manufacturing technology, control technology, sensing technology, and new materials, such as AC servo motors and drive systems, industrial control computers, motion control cards and bus systems, spindle oil mist lubrication cooling and gap sealing units, constant tension fast wire running systems, etc., making it suitable for slicing various hard and brittle materials, such as IC silicon wafers, photovoltaic cell substrate ultra-thin sheets, gallium arsenide, indium phosphide silicon carbide, lithium niobate, lithium tantalate, optical glass, etc.